To stay ahead of the competition, manufacturing companies are shifting toward low-volume, high-variability production. This shift demands highly flexible manufacturing systems, with assembly cells that can be reconfigured in no time.

By enabling ultra-reliable wireless communication between cell components and autonomous mobile robots moving parts or finished products across the shop floor, companies can reduce errors, prevent accidents and boost uptime.

The network challenge

Wi-Fi and 5G are great at moving massive amounts of data quickly. But in industrial control applications, the priority isn’t speed — it’s reliability and latency. Losing or delaying even a few data packets can trigger control protocols like Profinet to enter safety mode, bringing the entire process to a halt.

AGVs and AMRs, for instance, must be able to stop on a dime when an emergency stop signal is sent

Cranes sometimes need to lift and move heavy or bulky loads in perfect sync, with zero room for error.

All these examples require a network that doesn’t lose or delay a control signal.

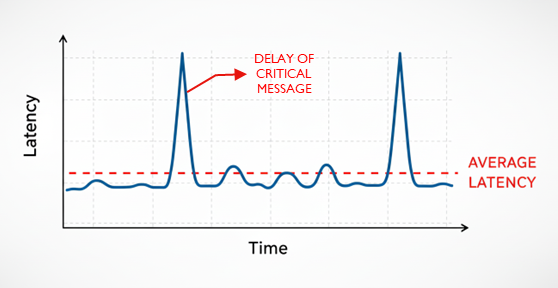

Traditional networks offer low average latency,

but can produce spikes with very high latency

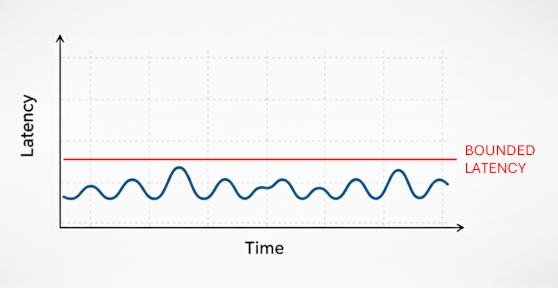

Better than Wired offers bounded latency,

meaning the latency is always under control

Either they’re retransmitted with some delay, or they are discarded. A user watching a video doesn’t notice that most of the times, but in industrial control such network behavior leads to failure and productions errors.

How we solved it - URLCC by design

URLLC — Ultra-Reliable Low Latency Communication — is the backbone of wireless machine-to-machine communication. When packets are lost or delayed, the consequences can be serious: wireless robots may stall or damage an expensive workpiece, safety protocols may fail and stop entire production lines, or autonomous vehicles may not react in time to an emergency stop.

That’s why Better than Wired, a spin-off from the imec research institute, has developed a breakthrough deterministic network technology. Built on Wi-Fi hardware but powered by innovative mechanisms, it guarantees that up to 99.9999% of data packets arrive within a specified delay. Reliability, bandwidth, and latency can be tailored to each application — with bounded latency as low as 2 milliseconds.

Our approach significantly improves overall system reliability, with a highly adaptable network stack built on our patented MAC and Spectrum Resource Management protocol. Each packet is treated individually based on its specific Quality of Service (QoS) requirements, enabling unprecedented capacity for maintaining bounded latency.

Benefits for the industry

URLLC for Industry 4.0

URLLC — Ultra-Reliable, Low-Latency Communication — minimizes both data packet loss and transmission delay to an absolute minimum. For industrial control processes, and especially for safety standards like ISO 3691-4 and the EU Machinery Regulation 2023/1230, this level of reliability isn’t optional — it’s mandatory.

That’s why URLLC is not an add-on, but a core design feature of the Better than Wired network.

License-free spectrum

You can use license-free bands, such as the ISM band used by Wi-Fi. This means you don’t need to make an agreement with your local regulator — or worse, with the regulator of each country if you’re a multinational company.

You also avoid paying monthly license fees to an operator or regulator.

Co-existence with other tech

Do you already have Wi-Fi, 5G, DECT, or another wireless technology installed? Through real-time sensing, each node in our network can independently detect and avoid interference in its immediate vicinity, eliminating the need for centralized decision-making or pre-planned configurations.

Even if someone fires up a rogue Wi-Fi access point in your warehouse, your production process or its safety won’t be impacted.

A mesh network

A mesh network means that every network participant can communicate peer-to-peer, without fixed “access points”. That’s a huge advantage in construction, agriculture or mining.

But also in factories and warehouses, this means that there are no network cabling, no extra network switches and no complex network configuration required.

Zero-touch installation

Install without worrying about wireless frequencies in use, or frequency maps. You can even set it up at a construction site or other temporary location, without involving your IT department (you should inform them, of course).

There’s no need to send multiple people to expensive trainings, or to worry that they’ll leave the company later.

Fix reception issues quickly

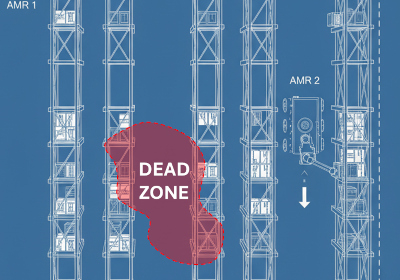

Do you have a temporary wireless reception “dead zone” because there’s new inventory in your warehouse, absorbing more radio waves?

Just temporarily deploy an extra BtW wireless node nearby and it will automatically repair the mesh network. No cables or network configuration are needed.

Minimal project lead times

When you want to launch a new (pilot) project with AMRs, wireless robots, or other wireless equipment, you want to start yesterday rather than today. But you often have to coordinate with multiple parties and wait until everyone can fit it into their schedules: your company’s IT department, the cabling team, your network partner for wireless planning, and so on. With Better than Wired, you can get started immediately:

- You can start without a new frequency planning, thanks to our interference avoidance.

- No need to upgrade your mobile and wireless networks to support URLLC.

- You can start without waiting for staff to be trained on these new features.

- No need to wait for extra network switches – we don’t use cables.

- You can proceed without consulting operators and regulators for licenses.

Bottom line: you might save up to half a year in project lead time and get your final project up and running, faster than you could get a pilot started with traditional wireless networks.

How do we relate to Wi-Fi, 5G, WirelessHART or ISA 100.11a?

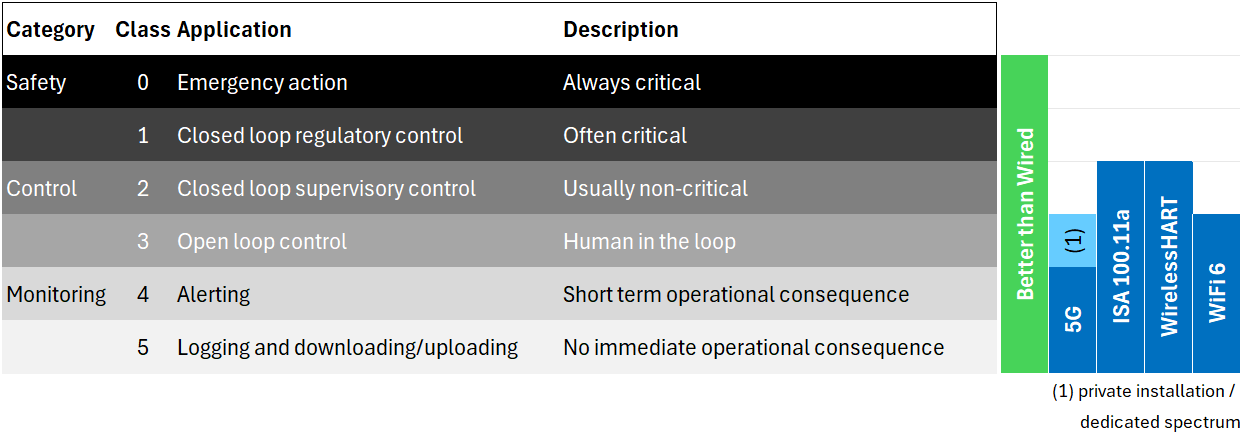

There are many types of wireless networks, each with its own strengths and weaknesses. There is no one-size-fits-all solution, meaning that in most cases you’ll need a hybrid approach. Wi-Fi or 5G, for instance, can offer extremely high throughput, making them ideal for users accessing information or streaming HD video.

Reliable 5G requires a spectrum license from an operator or regulator, while other technologies operate in license-free bands. License-free bands reduce both cost and complexity, but it can make the network vulnerable to interference from other networks on-site.

What most of these technologies have in common is that they are not designed for guaranteed data delivery with guaranteed latency. As mentioned above, they can experience temporary connection losses or delayed packets. This makes them unsuitable for Class 0 and Class 1 industrial applications, as defined by ISA.

Class 1 – Closed Loop Regulatory Control

This means that there’s a constant stream of control messages going back and forth between a controller and, for instance, a robot. These control loops require tight timings, for instance a control cycle of 10 milliseconds. When messages are lost or even delayed, for instance by a latency spike in the wireless network, the control cycle breaks down.

The Better than Wired system can wirelessly transport control protocols such as ProfiNet or CIP, to enable wireless Class 1 applications.

Class 0 – Emergency Action

Class 0 applications require a network that guarantees delivery and that guarantees it within a specific delay (bounded latency).

Manufacturers and system integrators need to do a safety assessment when deploying autonomous systems in live environments, for instance to enable a remote emergency stop in case of danger. Without a network that guarantees the timely delivery of the stop command, the safety assessment can become a hurdle and compliance with ISO 3691-4 or the European Machinery Directive becomes a challenge.

Better than Wired can wirelessly transport safety protocols (see our test results) such as ProfiSafe, CIP Safety or OpenSafety, or guarantee timely delivery of other safety messages.